In the coming two years, major changes in sensor technology lie ahead. With the exception of Fujifilm cameras based around EXR and X-Trans image sensors and the Foveon-based camera lineup from Sigma, almost every digital camera on the market today has a Bayer color filter array, named after inventor and Kodak scientist Bryce Bayer. Bayer filters have a significant drawback: they work by absorbing — and thereby: blocking — incoming light at each photodiode, allowing only certain ranges of wavelengths to pass. In the process, a very significant portion of the incoming light is blocked before it can reach the sensor. New sensor technologies are about to be introduced that waste less of the incoming light.

What’s an organic sensor? It increases the sensor’s saturation level while at the same time reducing noise by dumping silicon and using an organic layer instead.

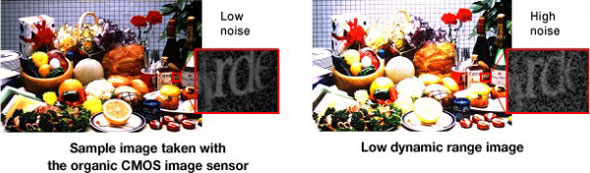

The new technology results in a nearly 10% better signal-to-noise (s/n) ratio than conventional silicon sensors. A 12dB s/n increase is expected to mean that the new sensor design is capable of gathering four times the light of a traditional design — or about 2 f-stops more dynamic range.

Typical camera sensors rely on silicon to trap photons and turn them into electrons. Fujifilm has pioneered the use of organic (carbon-based) compounds to do the same job. It was first granted a patent on the process in 2011, but a partnership with Panasonic is designed to bring the technology to life in a complete sensor implementation.

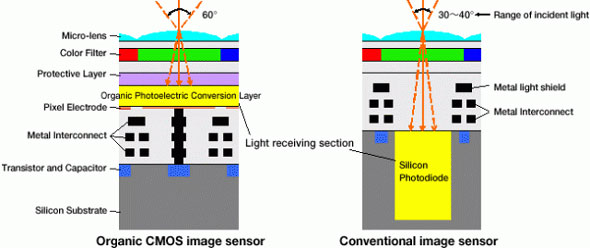

By placing the photosensitive layer on top of the electronics, the organic sensor design is expected to reach a nearly 100% fill factor — the percentage of the surface area sensitive to light — resulting in increased low-light sensitivity.

The increased absorption capability of the organic compounds also results in thinner sensors. The light-sensing layer can shrink from around 3 microns to 0.5 micron. This allows the sensor to capture light from a larger angle of incidence, as shown by the illustration above, providing yet more light sensitivity. The thinner photosites will also make it easier to design lenses, as the need to send light directly down into the photosites of current sensors is one factor driving up the cost of lenses for digital cameras.

The new sensor also has the potential reducing noise, as seen in the image below. Its designers are claiming reset noise as low as 3 electrons, well below the typical level for current designs. The combination of higher saturation and lower noise could make organic sensors a clear winner over current silicon-based versions.

Not much is yet know about Sony’s future sensor approach. Andrea of Sony Alpha Rumors tells me Sony is working on the same organic technology, according to a Sony patent. Their new sensor, says Andrea, will “not necessarily be Foveon-like, but certainly not Bayer. Coming at the earliest in 2015.”

Expect a major leap forward in sensor imaging technology within the next two years. Of course the competitors will observe each other and launch their new groundbreaking technologies accordingly.

Stay tuned, it will all be on THEME.